High temperature processing group

Our primary research fields are high temperature processing, bridging the gap between the fundamental study and industrial application for pyrometallurgical production and refining of metals.

Our research interests include:

- Thermodynamic and phase equilibria of metallurgical slags

- Physiochemical properties of high temperature melts, e.g. viscosity, thermal and electrical conductivity, density

- Fluid dynamics of bath smelting techniques

- Development of advanced refractories

- Secondary steel refining and inclusion control

- Microalloyed and oxide metallurgy of advanced steels

Experimental Facilities and thermodynamic software

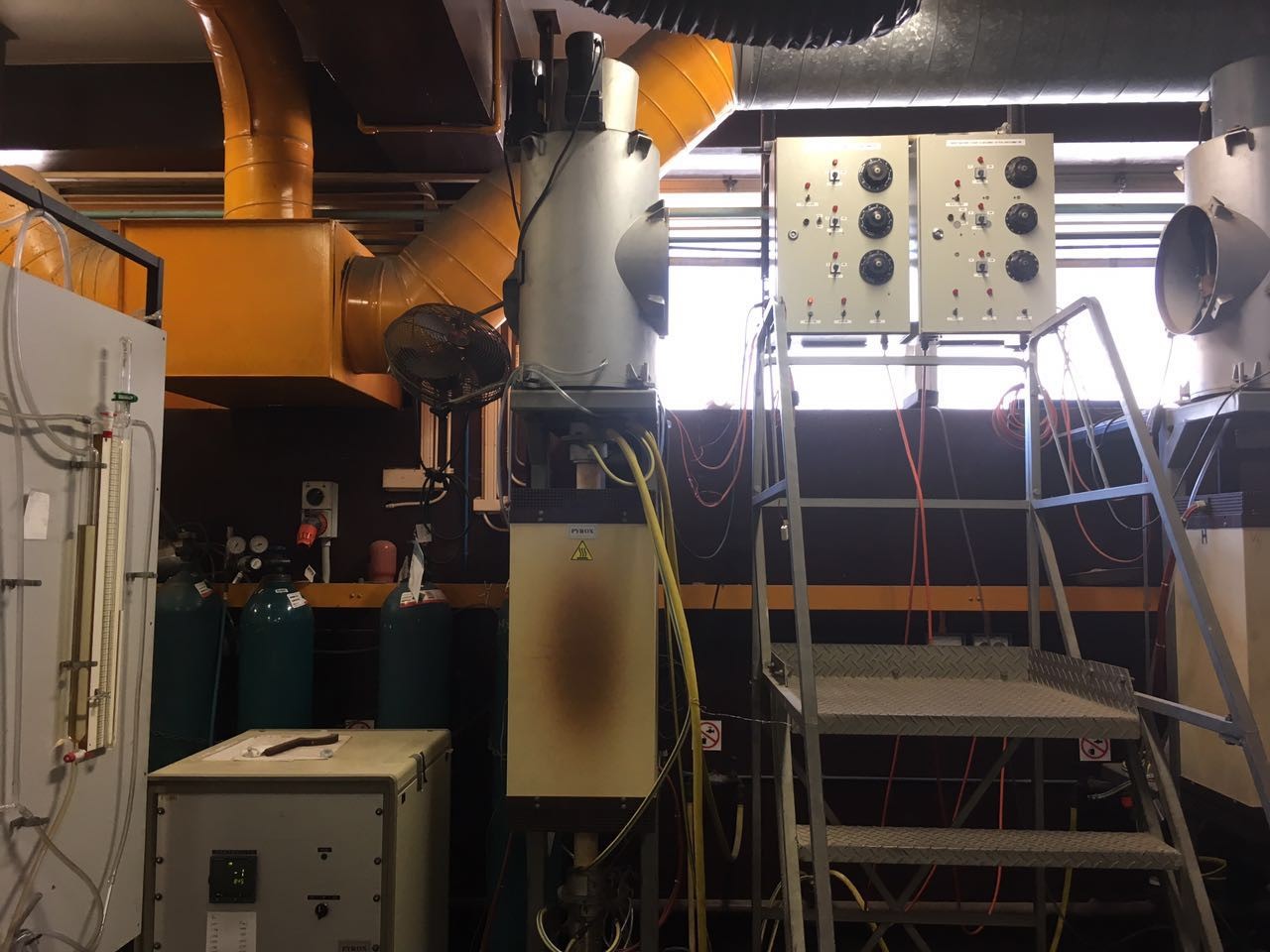

1. Advanced High Temperature Furnaces

Electric resistance furnaces are featured with lanthanum chromate heating elements, heating temperature up to 1650 °C, and controllable heating and cooling rate by program.

Electric resistance furnaces are featured with lanthanum chromate heating elements, heating temperature up to 1650 °C, and controllable heating and cooling rate by program.

The furnaces are modified to fit the requirements of various high temperature experiments, e.g. sealed system with controllable gas composition, accurate temperature monitoring, moving and spinning of samples at the hot zone, as well as quenching of the samples.

A series of high temperature experiments such as phase equilibria, viscosity, reaction kinetics, chemical corrosion of refractories, heat treatment as well as de-oxidation of steel refining can be well conducted using the advanced furnaces.

A series of high temperature experiments such as phase equilibria, viscosity, reaction kinetics, chemical corrosion of refractories, heat treatment as well as de-oxidation of steel refining can be well conducted using the advanced furnaces.